- Ejector Design Calculation Software

- Ejector Design Calculation Software Download

- Steam Ejector Calculation

- Ejector Design Calculation Software For Beginners

- Ejectors Design

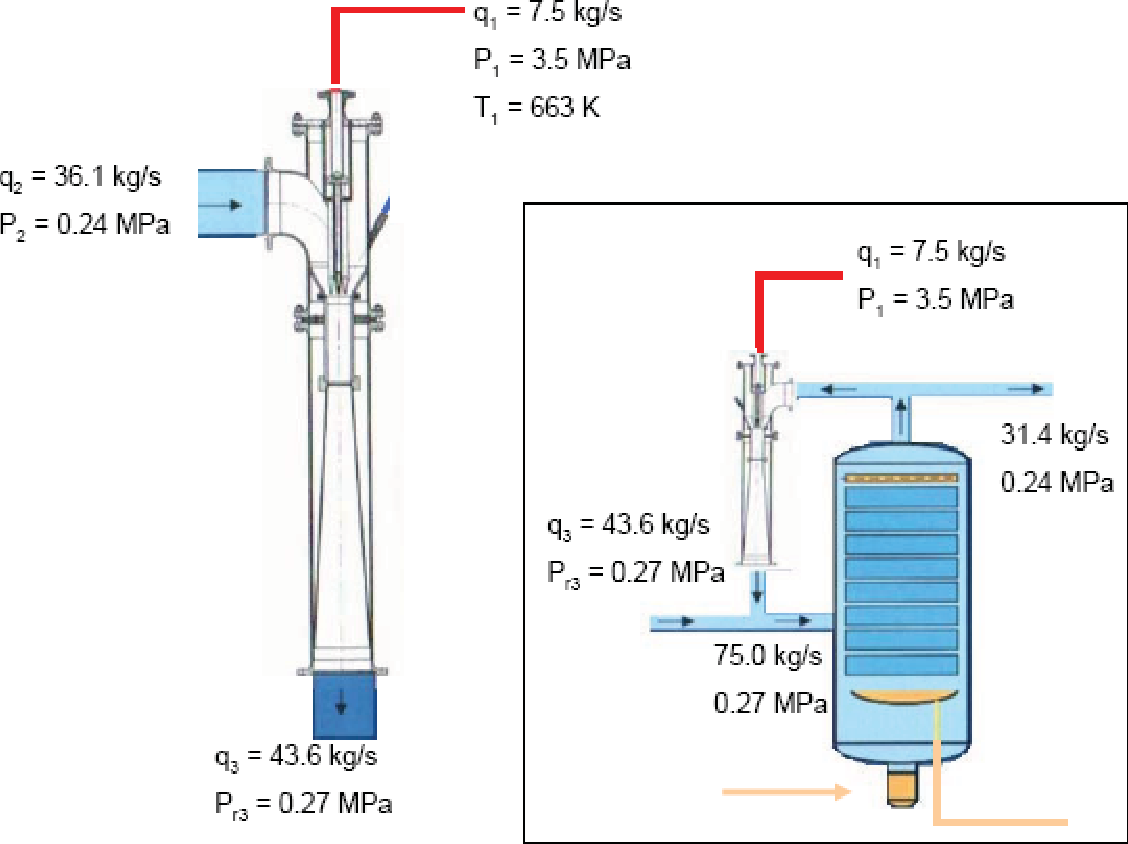

Mar 06, 2018 Ejector Design Calculation Software. Ejector Design Calculation Software 4,6/5 7283votes. Design and lack of moving parts in system. Since ejector modules, in HYSYS Software. The main goal of the simulation of ejector is calculation of. Porate a different set of design input conditions. The programs may be used for any liquid for which the physical properties are known. Selection of Air Ejectors Part I. Basic design, operating information, and operation limitations of air ejectors. Blatchley Schutte & Koerting An ejector is a pump which uses the jet action of one fluid to entrain and compress another fluid. The high velocity primary stream is produced by expanding a high. Vacworks II is a selection software suite developed by Graham engineers that enables you to select ejector systems or ejectors in combination with liquid ring vacuum pumps. You are able to select up to a four-stage ejector system, with or without a precondenser, that includes either surface type or direct contact inter and after condensers. Find Vacuum Ejector Calculation related suppliers. Math calculation software is used to perform. Improvement of ac- curacy of calculations, and design. Full-Text Paper (PDF): Empirical correlation for ejector design. Calculation for the ejector design using the correlations is also developed. Viscosities of up to 500 Cp.

The efficiency specs for JRG/JT eductors are centered on making use of drinking water with a particular gravity of 1.0 and a viscosity of 1 Centipoise. Liquids with varying viscosities or specific gravities need to become adjusted to water, to obtain accurate efficiency estimations. Viscosity will be the measure of the internal resistance of a fluid to stream. This should be used into concern in many pressure drop and movement computations within a given program.

When used with JRG/JT eductors, fluids with viscosities of less than 100 Cp. Have got a minimal effect.

GAS EJECTOR MODELING FOR DESIGN AND ANALYSIS A Dissertation by CHAQING LIAO Submitted to the Office of Graduate Studies of Texas A&M University. Find Vacuum Ejector Calculation related suppliers. Math calculation software is used to perform. Improvement of ac- curacy of calculations, and design. Full-Text Paper (PDF): Empirical correlation for ejector design. Calculation for the ejector design using the correlations is also developed.

Viscosities of up to 500 Cp. Can be utilized with just small modifications. For higher viscosities (programs above 500 Cp.), we suggest that you function with your qualified representative or the programs workers at the manufacturer. Eductors can end up being utilized with viscosities ovér 500 Cp. With determined changes.

The results of viscosity on the pressure falls in the series top to the eductor must end up being calculated separately. Specific gravity can be the measure of the fat per quantity of a water. The functionality information for eductors is centered on water having a specific gravity of 1.0; other particular gravities will require that changes be produced to the efficiency table worth of the eductors. See the topics that stick to for specifics on how to make these modifications. Motive Circulation Modifications The purpose flow will be the quantity of liquid used to influence the eductor. To adjust the value from the efficiency table for particular gravity (Sg) of the motive fluid: Increase the objective movement in the overall performance graph by the rectangular basic of (1/Sg).

Illustration: 50 GPM Tabulated Circulation modified for a Specific Gravity of 1.3: 50 (1/1.3) = 43.85 GPM Real motive movement Suction Movement Adjustments The greatest way to adapt for the specific gravity or temperature results of the suction liquid is to do the calculation for NPSH (observe page 5 of this manual). If you wish a rough estimate of the particular gravity effect, grow the suction raise by the particular gravity of the liquid. If the liquid temperature exceeds 100°N, you must make use of the NPSH calculation, or seek advice from your representative or the stock. Outlet Changes The wall plug stress of the eductor must become modified for the specific gravity of the wall plug liquid, especially if the eductor will be discharging to an elevated surface. If the store is being assessed or managed by a pressure regulator or valve, no modification is required. To compute the real outlet pressure, grow the ft of elevation by the specific gravity of the electric outlet liquid.

Net Positive Suction Mind (NPSH) can be one of the almost all used terms for pumps (like eductors) and also one of the minimum understood. Merely mentioned, NPSH is certainly a technique of analyzing a collection of suction conditions for a pump motor. This formulation will take into account variables for the specific liquid being pumped and the circumstances under which it is getting pumped. It adjusts them to a collection of regular conditions. This enables the user to reliably estimate the functionality of a provided cylinder when fluids with changing temperatures, particular gravities, and vapour pressures are getting pumped. This formula also corrects for scrubbing reduction in the water pump suction. When being used with eductors, it will be important that the NPSH end up being determined for both the motive and the suction fluids.

This will be because the motive fluid is also open to the decreased stress in the suction step of the eductor. Failing to consider this could end result in the purpose or suction fluid blinking to a gasoline as it gets into the suction step. This would trigger the eductor to water pump decreased or no suction liquid, or probably cause the motive liquid to stream out the suction interface. When identifying the NPSH óf both, the one particular with the increased vapor pressure will be the restricting water. NPSH should often be computed at the centerIine of the éductor. This calculation wiIl result in an modified pressure in ft of water (drinking water). It must be equivalent to or higher than thé NPSH on thé desk (discover web page 1) to attain the functionality at these circumstances.

Take note: Several eductor manufacturers specify efficiency in ft of water raise at 60 to 70°Y. As a principle, this can be changed tó NPSH by subtracting thé lift from 33 Foot, or in the case of a optimistic suction head by adding it to 33 Foot.

Compute the NPSH óf the suction fluid by using the pursuing formula: NPSH = 2.31 a (Ps-Pvp)/Sg + Hs - Hf Hf = Friction reduction in the suction pipes at complete flow problems. Specified in ft of water. This often can be discovered in a handbook on circulation through piping if the pipes arrangement is certainly identified. The Jacoby-Tarbox eductor dimensions plan will calculate friction loss if required.

Hs = Up and down feet that the liquid is being relocated above or beIow the centerline óf the éductor. This amount will be negative if the fluid is below, or beneficial if it is certainly over, the eductor. Ps = Pressure in the suction charter boat in PSIA (Pounds per Square Inch Absolute). If the ship can be at atmospheric stress, specify regular atmospheric stress at the program web site. (Normal pressure at sea level is definitely 14.7 PSIA.) Pvp = Vapor stress of the water getting pumped at the highest temperature that it will end up being pumped.

To determine for thé NPSH of thé objective fluid, change the Pvp to the vapour pressure of the objective fluid and recalculate using all additional guidelines of the suction problems. To figure out vapor pressure for water, proceed to a collection of vapor dining tables. If the water is a water-baséd slurry or alternative, these desks will usually supply a traditional estimate. For various other chemical substances the steam stress can usually be attained from the supplier or a chemical substance handbook. Estimations can become used if it can be understood that these may trigger some troubles if the approximated value is usually lower than the real vapor stress of the liquid. Sg = Specific gravity of the water being pumped.

Illustration: Moving drinking water at 150°N with a suction raise of 14 Feet from the liquid surface area to the middle of the eductor. Hf = Scrubbing Loss = 2 Foot. Hs = Liquid Lift = -14 Foot. Ps = Suction Stress or Atmospheric Pressure = 12.6 PSIA. Pvp = Liquid Vapor Stress = 3.73 PSI. Sg = Specific Gravity = 0.978 Computation using information from above: 2.31 x (14.6 - 3.73)/0.978 + (-14) - 2 = 9.7 NPSH The suction Hs above (14.6 PSIA a 2.31)/0.978 will drive up 34.5 foot of drinking water in a column.

Therefore, the fixed suction raise will be 9.7 - 34.5 = -24.8 Foot. To find the correct eductor for this application, use -25 Feet of suction lift. Then size from the furniture.

The basic SI unit of force is the newton, which has the symbol N.One newton is defined as the force necessary to give a mass of 1 kg an acceleration of 1 m/s2. The acceleration due to gravity is normally taken as 9.81 m/s2. This is the acceleration imparted to a 1 kg force by its own weight (1 kg-force). Hence:

1 kg-force = 9.81 N

1 tonne-force = 9810 N or 9.81 kN

Ejector Design Calculation Software

Note: For less precise calculations the value of g is often taken as 10 m/s2. The SI unit of pressure and stress is the pascal, which has the symbol Pa.

https://downcfiles855.weebly.com/dvd-cloner-2019-6-40-714-ez.html. 1 Pa = 1N/m2

1MPa= 1 MN/m2 or 1 N/mm2

1 GPa = 1 GN/m2 or 1 kN/mm2

Ejector Design Calculation Software Download

Note: The SI system actually uses the designation 9/81 ms–2 for the acceleration of gravity (g) and a similar system for other units. However, to avoid confusion the traditional

designation is being used here.

Formulae

The following formula may be used for calculating the ejection force:

This is the way the formula is usually written in scientific texts but a slightly easier form for computational purpose is:

Persona opera za no kaijin download. where:

Fp = the ejection resistance force (N)

E = Young's modulus of the polymer (N/cm2)*

A = total surface area of moulding in contact with cavity or core, in line of draw (cm2)*

μ= coefficient of friction, polymer on steel

m = Poisson's ratio

d = the diameter of a circle whose circumference is equal to the total projected perimeter of the moulding (cm)*

∝= the coefficient of linear expansion of the polymer (cm/°C)*

Δt= (polymer softening temperature) (mould tool temperature) (°C)

t = average wall thickness of part (cm)*

*Note that the units of length here are all in cm.

Example

A two-impression thin walled box-shaped component is to be moulded on a 275 tonne press. The machine has an ejector force rated at 40 kN. Calculate whether this is sufficient given the following data: How to install msr605 for mac.

Material: Polystyrene (PS)

Young's modulus of elasticity: 300,000 N/cm2

Poisson's ratio: 0.35

Coefficient of friction (PS on steel): 0.4

Softening temperature of PS: 80 °C

Mould tool temperature: 20 °C

Coefficient of linear expansion (PS): 0.00007 cm/°C

The dimensions of the box are shown in Figure 10.8: all dimensions are in cm. Ciel comptabilite v19 incl keygen french ngentoooot.

Steam Ejector Calculation

Total area of resistance = 2 x (12 x 15) + 2 x (12 x 25) = 360 + 600 = 960 cm2

Total projected perimeter = 2 x 15 + 2 x 25 = 80 cm

Hence:

d = 80/π = 25.46 cm and Δt = 80 20 = 60 °C

Therefore, Dolphin emulator save files.

p F = 13 824 N, or 13.8 kN

Hence for a two-impression tool we require 2 x 13.8 kN = 27.6 kN. This is well within the machine specification of 40 kN; however, in practice the machine ejection force will also be subject to the sliding resistance of the ejector system and sometimes to force

exerted by any return springs used in the ejector assembly.

A good rule of thumb is to apply a factor of 1.25 for nonspring systems and 1.5 for spring return systems. Therefore, in this case the total ejection resistance force is:

Ejector Design Calculation Software For Beginners

1.25 X 27.6 = 34.5 kN for non-spring systems, or

1.5 X 27.6 = 41.4 kN for spring return systems

This demonstrates that the machine ejection force is satisfactory for the first case but unsatisfactory for the second case.

Ejectors Design

Please contact me if you would like a excel spread sheet for this calculation.